Product Introduction

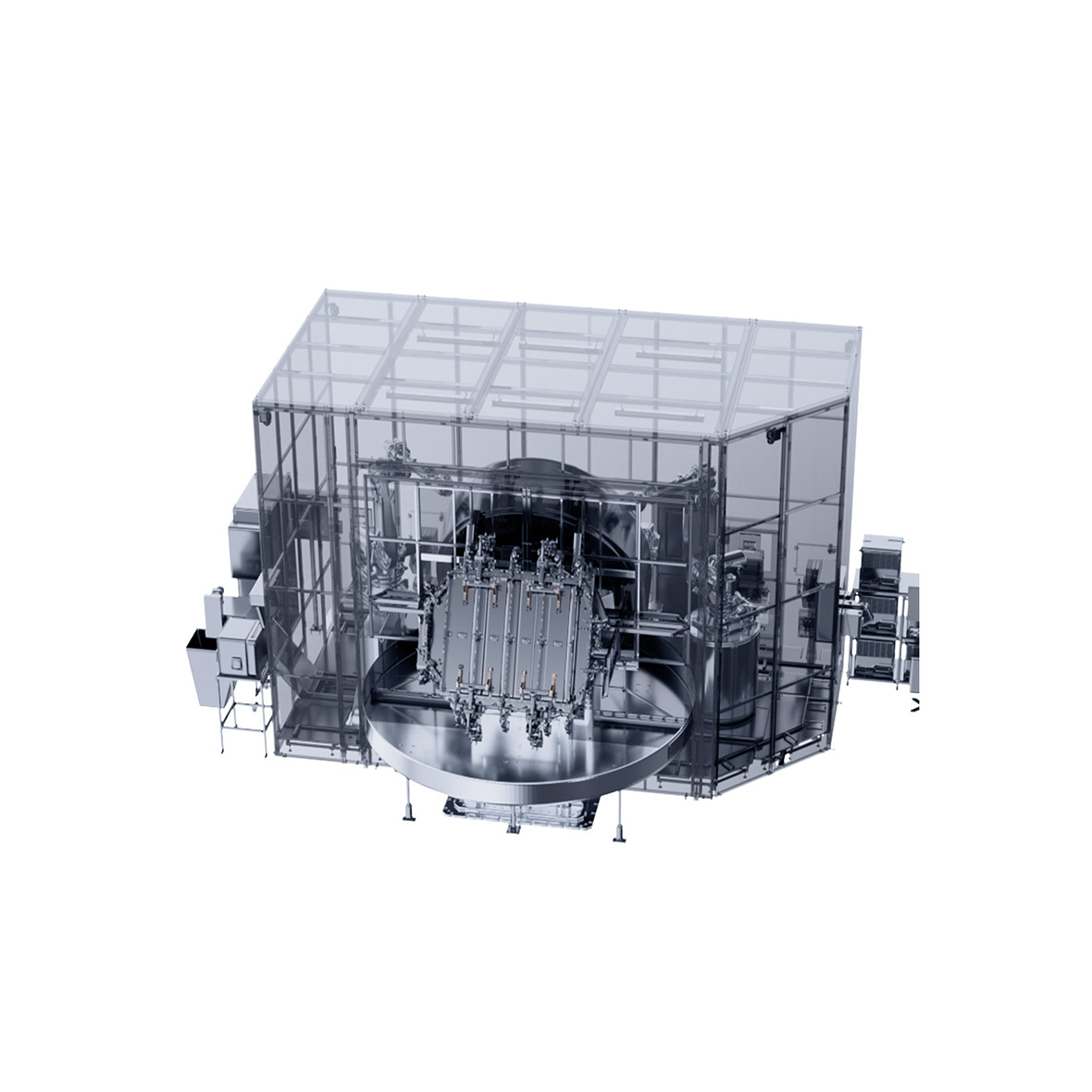

The automatic grinding workstation uses multiple robots for collaborative processing, combined with real-time force feedback, precision adjustment, and advanced sensing technologies. It provides a safe, stable, and efficient solution for grinding operations of new energy vehicle battery pack enclosures.

Technical Specifications

| Item | Specification |

|---|---|

| Cycle Time | 206s (depending on the process) |

| Product Weight | 100 kg |

| Product Dimensions | 2304 × 690 × 260 mm |

| Workstations | 4 units |

| Equipment Configuration | 3-axis dual-spindle high-speed deburring machine |

| Functions | FSW deburring; module brushing; edge deburring; window brushing & edge/window cleaning |

Product Features

-

StandardizationStandardized solution

-

ModularityModular brushing units, modular design

-

High IntegrationMulti-process and multi-robot collaborative machining

-

High PrecisionReal-time force feedback and precise dynamic adjustment

Application scenarios

-

Widely used in automotive manufacturing, new energy, general industry, and machinery industries

Differentiated Competitiveness

-

Modular and standardized integrated production

-

Digitalized production and management