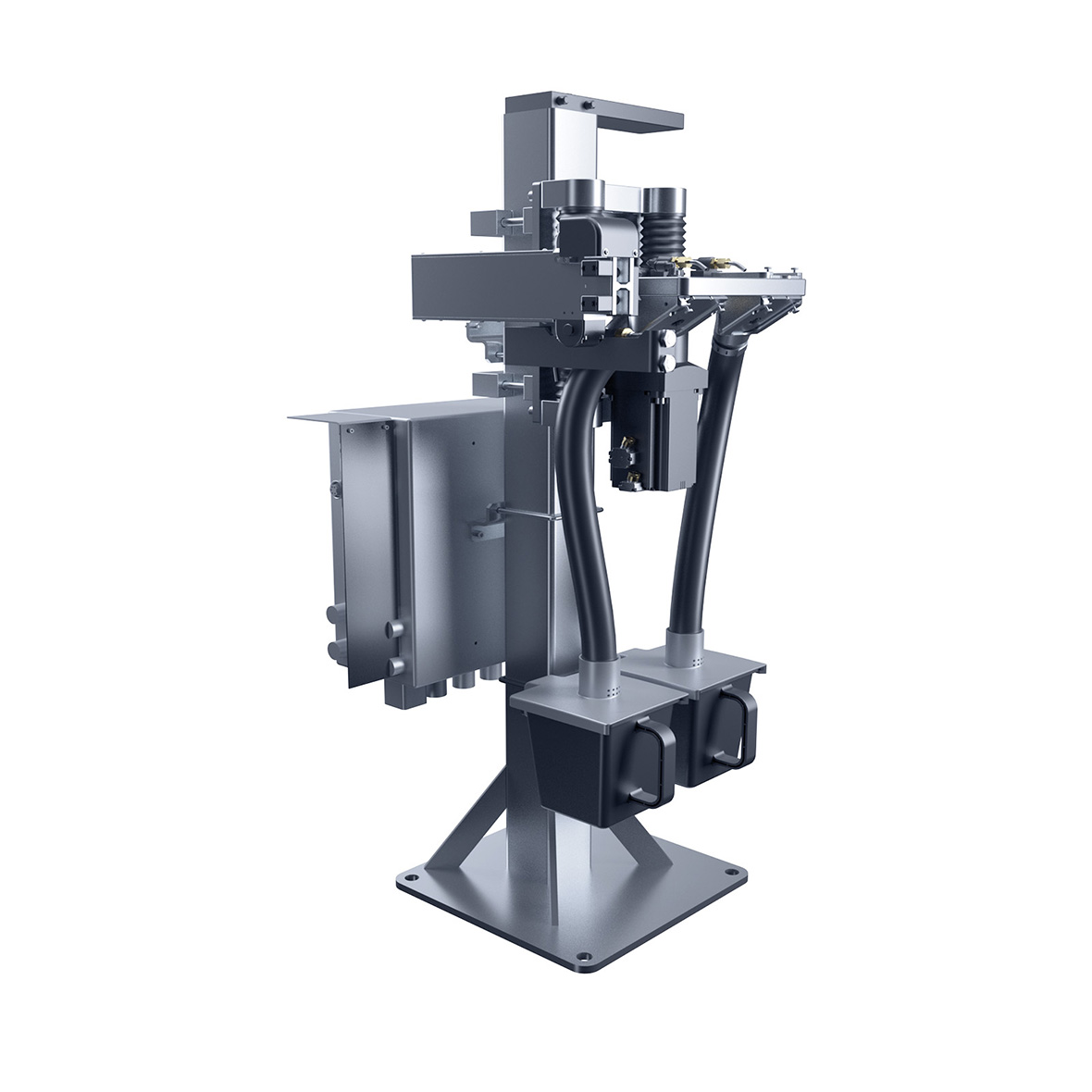

Product Introduction

The new-generation Tip Former & Cap Changer adopts servo drive technology, integrating reshaping, alignment, and cap replacement into one system. It offers advantages such as compact structure, excellent welding tightness, short cap-changing time, and zero need for spare cap inventory.

Technical Specifications

| Indicator Name | Industry Standard | Mino | Difference |

|---|---|---|---|

| Cap Changing Cycle (s) | 24 | 18 | ↓ 25% |

| Electrode Cap Storage Quantity (pcs) | 16 | 32 | ↑ 100% |

| Cap Insertion Depth (mm) | 45 | 40 | ↓ 11% |

| Cap Wall Thickness (mm) | 30 | 20 | ↓ 33% |

Product Features

-

High EfficiencyAchieved through synchronous retrieval and detection technology

-

High CompatibilitySupports both small-diameter spot welding caps and threaded electrode arms

-

High ReliabilityTriple-guide design with pull-out cap extraction

-

High BenefitIntegrated reshaping function can extend electrode cap lifespan by 4–8 times

Application Scenario

-

Mino’s Tip Former & Cap Changer is an intelligent device supporting welding production lines. It is mainly used for automatic replacement and reshaping of spot welding electrode caps.