Product Introduction

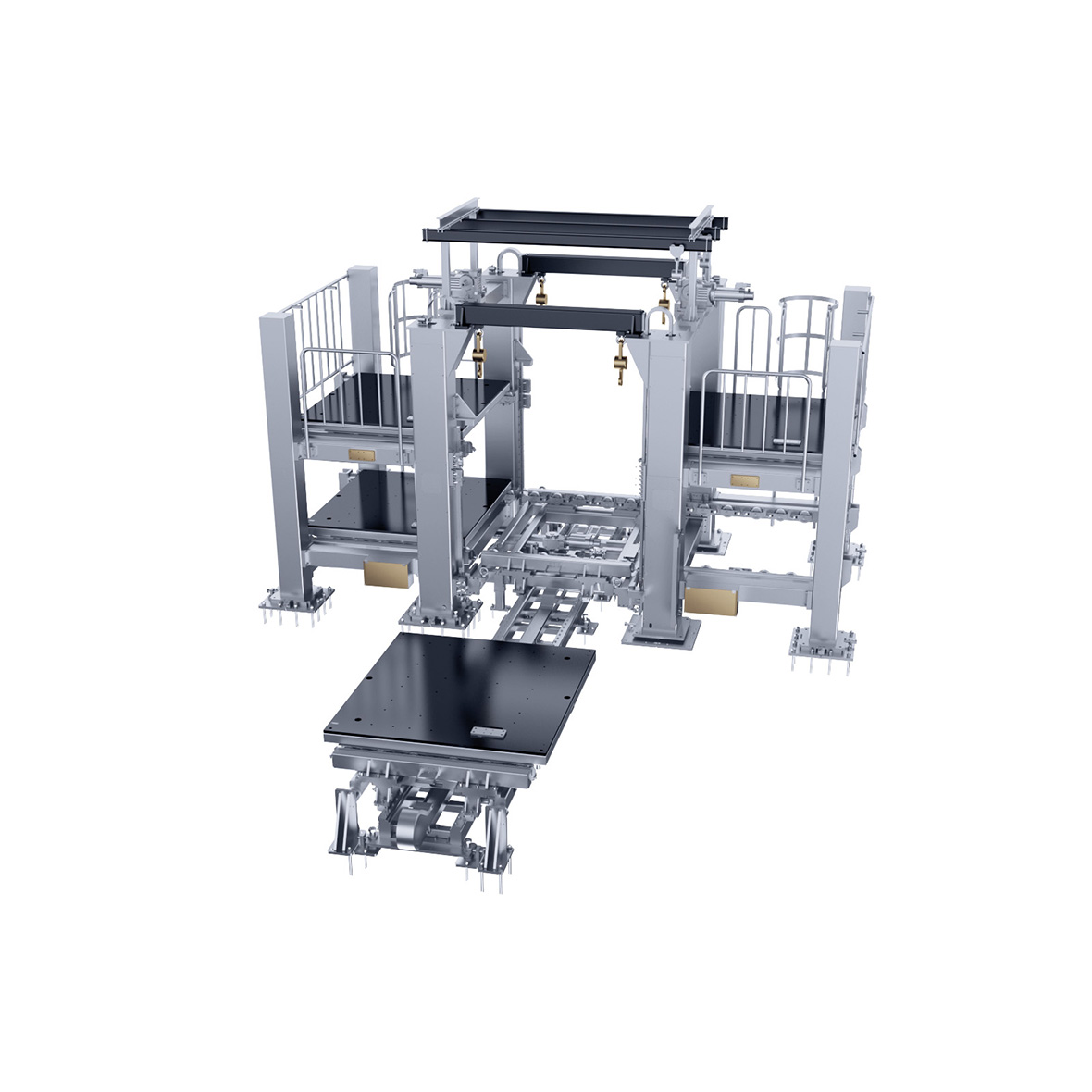

The Tooling Storage System is designed for flexible production lines of multiple vehicle models in underbody assembly, four-door and two-cover stations, side body, and floor assembly stations. It provides precise positioning and intelligent storage and switching of tooling. With a modular layout and flexible configuration, it can be adapted to various customer site requirements.

Technical Specifications

| Indicator Name | Industry Standard | Mino | Difference |

|---|---|---|---|

| Motor and Drive Quantity (set) | 5 | 2 | ↓ 60% |

| Floor Area for 6 Tooling Positions (㎡) | 59 | 25 | ↓ 40.6% |

| Repeat Positioning Accuracy (mm) | Manual Clamping | Automatic Clamping | — |

| Dynamic Load Capacity (kN) | ±0.15 | ±0.1 | ↑ 50% |

Product Features

-

High repeatability ensures precise alignment of vehicle body parts, guaranteeing body assembly quality

-

Standard unit only requires 2 sets of motors and drive systems for tool switching

-

Easy addition of new vehicle models; no need to upgrade motor and drive systems, enabling immediate production

Application scenarios

-

Used for flexible positioning, storage, and switching of tooling in underbody, four-door/two-cover, side body, and floor assembly stations of high-variation production lines

-

Modular design allows for flexible combinations and layout configurations to meet diverse customer needs